Insight

H20 Wooden Beam: 4 Common Formwork Mistakes and How to Fix Them

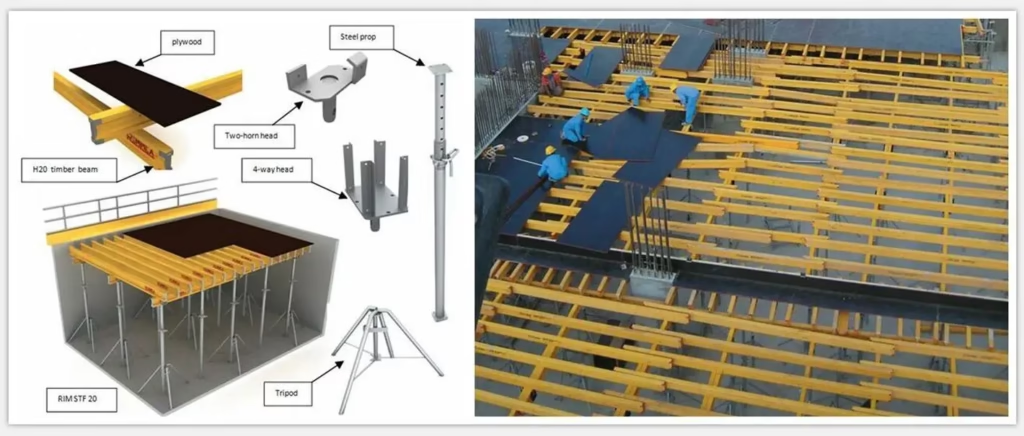

In modern construction, the H20 Wooden Beam serves as an indispensable component for floor and wall formwork systems. Known for its high load-bearing capacity and flexibility, this engineered beam significantly accelerates project timelines. However, incorrect application can lead to material waste and serious structural safety risks.

The following guide outlines the 4 most common mistakes when using H20 beams and provides definitive solutions for contractors to ensure optimal performance.

1. Incorrect Load Calculation and Beam Spacing

Common Mistake: Many construction teams rely on intuition rather than engineering data to determine beam spacing. Placing beams too far apart or pouring concrete layers thicker than the design allows causes the beams to sag, crack, or fail abruptly. This happens when the actual load exceeds the rated bending moment, typically 5.0kNm.

The Fix:

- Always strictly adhere to the formwork design drawings calculated by structural engineers based on slab thickness and the weight of wet concrete.

- Consult the manufacturer’s load charts. For instance, with a beam span of $2.0 \text{ m}$, the allowable load is generally limited to $5.0 \text{ kN/m}$. If the actual load is higher, you must reduce the spacing between the supports (scaffolding).

2. Improper Storage in Prolonged Wet Conditions

Common Mistake: Although a high-quality H20 Wooden Beam is treated with a waterproof coating, leaving beams in direct contact with damp ground or exposed to heavy rain without cover will compromise the wood’s structural integrity. Moisture penetration into the core causes delamination of the adhesive and rot within the web section.

The Fix:

- Store beams in a dry, covered area or under waterproof tarpaulins when not in use.

- Use racks to keep beams at least $15-20 \text{ cm}$ off the ground to prevent moisture wicking. Maintaining a dry state can extend the service life of the beams by 2 to 3 times.

3. Faulty Installation of Supports and Accessories

Common Mistake: Placing H20 beams on U-heads that do not match their dimensions or failing to center the beam on its support. This creates uneven concentrated stress, which can crush the beam flange or cause the formwork system to become unstable and tilt during concrete vibration.

The Fix:

- Ensure the beam is securely and centrally seated within the U-head.

- At joining points or supports, use specialized clamps to fix the beams in place, ensuring they do not slide or overturn during the pouring process.

4. Utilization of Damaged or Deformed Beams

Common Mistake: Reusing beams that have cracked webs, broken ends, or visible signs of internal rot. These beams no longer meet the standard flexural stiffness of $EI = 450 \text{ kNm}^2$, making them a “weak link” that threatens the safety of the entire floor slab.

The Fix:

- Implement a rigorous material inspection process before assembly. Any beam with longitudinal cracks in the flange or significant mechanical deformation must be decommissioned immediately.

- Prioritize using beams with plastic or metal end caps to protect the corners from impact damage during transport and stripping.

Conclusion

Using the H20 Wooden Beam correctly is more than a technical requirement; it is a critical factor for site safety and optimizing material investment. By understanding these common mistakes and applying the correct fixes, contractors can maximize the efficiency and longevity of their H20 formwork systems.