Insight

How are wooden pallets made?

Wooden pallets are essential for the efficient transportation and storage of goods. They provide a sturdy and reliable platform for stacking and moving products. But how are these ubiquitous structures actually made? Let’s take a look at the process.

Standards for exporting wooden pallets

- Must have a certificate from the International Plant Protection Convention (IPPC). This certificate is to ensure the safety of agriculture in each country. Avoid contamination from pests from one country to another. (This is the reason why all foods brought before leaving the country will be confiscated and destroyed at the airport.)

- Must have a moisture content below 18%. (Need to be dried, this step costs a lot in production)

- Must be suitable for warehouses and containers

Wooden pallets manufacturing process

1. Material selection

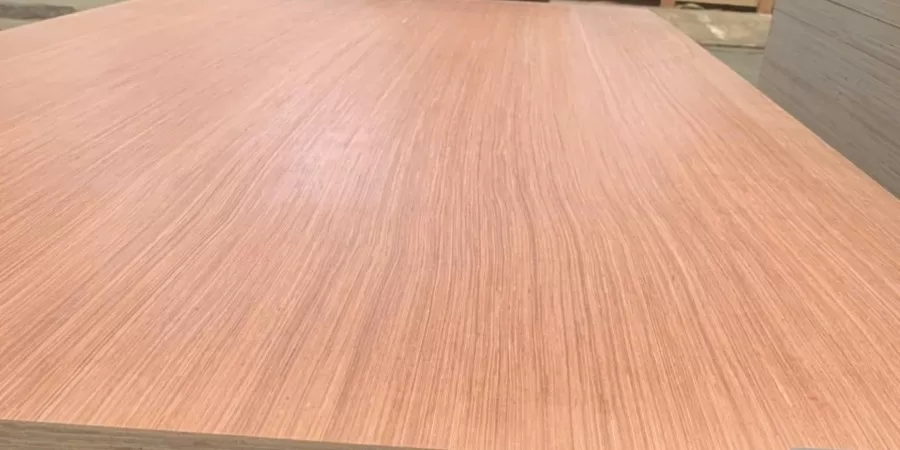

The first step of wooden pallet manufacturing is obviously the selection of the material. Pallet manufacturers choose wood as the main material because of wood’s durability, availability, and ease of repair.

The type of wood used for a pallet depends on its intended use. Softwoods like pine are often used for lighter-duty pallets, while hardwoods like oak are better suited for heavier loads. The wood is always sourced from sustainable forests to ensure environmental responsibility.

2. Cutting and Shaping

Once the wood is selected, it undergoes precision cutting and shaping to create the various components of the pallet. The deckboards are cut to uniform sizes, while the stringers or blocks are shaped to the required dimensions. Precision in this phase is crucial to ensure the pallet’s structural integrity.

3. Assembly

The wooden pieces are assembled into the desired pallet configuration. This typically involves nailing or screwing the components together.

4. Quality control

The finished pallets are inspected to ensure they meet the required specifications and are free from defects.

5. Heat Treatment

Pure wood has to be treated under the ISPM15 international regulations to prevent the spread of pests and fungi. The wood must be heated to a minimum of 56 degrees celsius (over 30 minutes). The treatment kills pests and minimises the moisture content of the wood, making for lighter pallets. Engineered wood is exempt from ISPM15 as pests would have been destroyed by heating and gluing during the manufacturing process.

6. Packaging and Shipping

The finished pallets are bundled and prepared for shipment to customers.

Wooden pallets are a versatile and durable packaging solution. They are essential for the efficient movement of goods within supply chains and play a crucial role in global trade.